Industrial Internet of Things: A Complete Overview of Benefits & Applications

“If you think the internet has changed your life, think again. The Internet of Things is about to change it again”.

– Brendan O’ Brien (Engineer, American record producer, musician)

The Internet has taken over our lives in many ways, impacting everything from how we do our shopping and communicate with friends and family to how we run our businesses.

With the introduction of the Industrial Internet of things (IIoT) or IoT, manufacturing has undergone a profound transformation, resulting in greater efficiency and productivity.

Industrial IoT has been the hottest topic in recent years. The global market of IoT in the manufacturing market will grow at a Compound Annual Growth Rate of 10.1%, from $ 33.2 billion in 2020 to $ 53.8 billion in 2025. What is the Industrial Internet of things?

In this article, we’ll answer these questions and more as we take a comprehensive look at industrial IoT, exploring its key concepts, benefits, and applications.

What is IIoT?

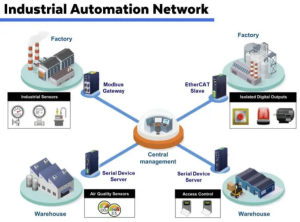

The industrial Internet of things (IIoT) uses connected sensors and devices to collect and analyze data in real-time to improve industrial operations. It helps businesses identify problems and opportunities for improvement and make better-informed decisions.

The industrial Internet of things (IIoT) uses connected sensors and devices to collect and analyze data in real-time to improve industrial operations. It helps businesses identify problems and opportunities for improvement and make better-informed decisions.

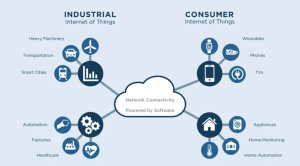

What’s the difference between IIoT and IoT?

The main difference between IIoT and regular IoT is that IIoT focuses on industrial applications. In contrast, regular IoT can be used in various industries, including manufacturing, healthcare, retail, etc.

The main difference between IIoT and regular IoT is that IIoT focuses on industrial applications. In contrast, regular IoT can be used in various industries, including manufacturing, healthcare, retail, etc.

For example, you might have a connected thermostat in your home that you can control from your smartphone. It would be an example of regular IoT. In contrast, IIoT might be used to monitor the temperature of industrial ovens in a factory to ensure that products are being manufactured correctly.

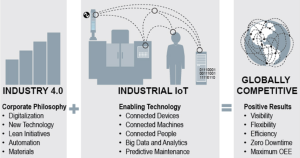

IIoT vs. Industry 4.0

Industry 4.0 is often used synonymously with industrial IoT, but there are some differences between the two concepts.

While industrial IoT focuses on analyzing data from connected devices and systems to improve industrial processes, Industry 4.0 involves incorporating innovative manufacturing technologies into industrial operations to increase efficiency, productivity, and flexibility.

For example, IIoT might involve using sensor data to monitor the health of industrial equipment. In contrast, Industry 4.0 could involve using connected robots and machine learning algorithms to increase efficiency in industrial processes.

Top Benefits of IIoT

1. Increased Efficiency & Productivity

The industrial internet of things allows companies to track industrial processes and equipment in real-time, identify problems or opportunities for improvement, and make data-driven decisions that can help increase manufacturing efficiency.

For example, industrial IoT can monitor the performance of industrial equipment and make predictive maintenance decisions that can help reduce downtime and improve productivity.

2. Reduced Costs & Overhead

Cost savings is one of the most common benefits of the industrial internet of things. Companies can save on labor, energy, and other operational expenses by using the industrial internet of things to collect data and optimize industrial processes.

For example, industrial IoT can automate repetitive tasks, such as material handling or quality control. It can help reduce manual labor, leading to cost savings.

3. Improved Safety & Security

Industrial IoT can help improve safety by providing companies with real-time data about industrial processes and equipment. This data can identify potential safety hazards and take action to prevent accidents.

The technology improves security by providing data about who has access to industrial equipment and when. This information can secure industrial facilities and prevent unauthorized access.

4. Enhanced Decision Making

Decision-making is one of the most critical aspects of industrial operations. By collecting data and analyzing it in real-time, industrial IoT can provide companies with the information to make better-informed decisions.

This data can improve production planning, optimize inventory management, and make other strategic decisions that can help improve industrial operations.

5. Enhanced Reliability

IIoT can monitor industrial equipment and predict when maintenance or repairs will be necessary. This information can help companies schedule downtime for maintenance or repairs, preventing production disruptions.

For example, when an IIoT-enabled machine predicts that it will need maintenance soon, a message can be sent to the maintenance team to schedule repairs before the machine breaks down.

6. Increased Sustainability

The industrial internet of things can also help companies reduce their environmental impact by optimizing industrial processes and reducing energy consumption.

For example, when industrial equipment is monitored in real-time, companies can adjust the equipment to reduce energy consumption. It can help reduce industrial emissions and improve sustainability.

7. Higher Quality Products/Services

Work quality can be improved when industrial IoT monitors and controls industrial processes. By using data to identify problems in industrial processes, companies can make changes to improve the quality of their products or services.

For example-If industrial IoT detects that a machine is producing defective products, the company can take action to fix the problem and improve the quality of its products.

Top Applications of IIoT

Predictive Maintenance

Predictive maintenance is asset management that uses condition-monitoring data and analytics to predict when an asset will need maintenance. This information can schedule maintenance before the issue becomes critical, preventing downtime and saving on repair costs.

In the case of machinery, predictive maintenance can detect when a component is about to fail. The data collected by sensors on the machinery can be analyzed to identify patterns that indicate an impending failure. This information can then be used to schedule a repair or replacement before the component fails.

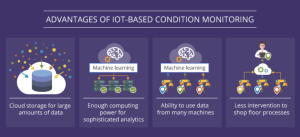

Condition-based Monitoring

The objective of condition-based monitoring is to continuously monitor equipment conditions and then use that information to decide when maintenance should be performed. This can be done using various methods such as vibration analysis, thermography, oil analysis, and visual inspection.

Condition-based monitoring can be used with predictive maintenance to provide a complete picture of an asset’s condition. While predictive maintenance looks at historical data to predict when an issue will occur, condition-based monitoring can be used to identify the problems already happening. This information can then be used to schedule repairs before the issue becomes more serious.

Asset Tracking & Management

IIoT systems can track assets throughout their lifecycle. This information can optimize maintenance schedules, improve utilization, and reduce downtime.

Asset tracking can also be used to monitor the location of critical assets in real-time. This information can be used to improve security and prevent theft or loss.

In addition, asset tracking data can create digital twins of physical assets. This information can simulate how the asset will perform under different conditions and identify potential issues before they occur.

Inventory Management

Managing inventory can be a time-consuming and error-prone process. IIoT systems can automate this process by tracking inventory levels in real-time and alerting staff when stock is low.

With IIoT, it is also possible to track the location of inventory in real-time. This information can be used to improve picking and shipping accuracy. In addition, IIoT systems can track the expiration dates of perishable items and alert staff when items need to be replaced.

For example, in the food and beverage industry, IIoT systems can track the temperature of perishable goods throughout the supply chain. This information can ensure that products are stored and transported under conditions that keep them fresh.

Quality Control & Assurance

IIoT systems can be used to automate quality control and assurance processes. For example, sensors can monitor the manufacturing process and identify when products do not meet specifications. This information can then be used to trigger corrective actions.

In addition, IIoT systems can collect data about product quality over time. This information can be used to identify trends and improve the manufacturing process.

Energy Management

The industrial internet of things can also manage energy consumption. There are many ways to do this, including monitoring energy use in real-time, setting limits on energy use, and automatically shutting off equipment when it is not in use.

With IIoT, it is also possible to optimize energy use by connecting different pieces of equipment and making them work together more efficiently. For example, an industrial fan can be connected to a temperature sensor. The fan can be turned off when the sensor detects that the room temperature has reached the desired level.

Environmental Monitoring

Environment conditions can have a significant impact on industrial operations. IIoT systems can monitor environmental conditions in real-time and take action to protect equipment or products.

Many different environmental conditions can be monitored, including temperature, humidity, and air quality. By monitoring these conditions, it is possible to take action to prevent issues such as corrosion, mold growth, and product degradation.

Security & Surveillance

The next IIot application is security and surveillance. By connecting cameras and other sensors to an IIoT platform, it is possible to create a surveillance system that can monitor activities in real-time. This information can improve security and prevent accidents or crimes.

For example, if an employee is working in a hazardous area, the surveillance system can monitor their activities and ensure they follow safety procedures. In addition, if there is an accident or crime, the surveillance system can help identify the responsible party.

Building Automation

Building automation is another common application of the industrial internet of things. By connecting different systems in a building, it is possible to create a system that can automatically control temperature, lighting, and security.

Building automation is another common application of the industrial internet of things. By connecting different systems in a building, it is possible to create a system that can automatically control temperature, lighting, and security.

The benefits of building automation include improved comfort, energy savings, and increased security. In addition, building automation systems can be used to monitor activities in the building and take action in an emergency.

Read Also: 5 Predictions for the Future of IoT and Mobile App Integration

Concluding Thoughts

The industrial internet of things describes the networking of physical objects and devices, such as machines, vehicles, and buildings, with communication capabilities. IIoT has gained traction in recent years due to the continued growth of the IoT market and the increasing demand for data-driven decision-making across all industries.

This article provides a comprehensive overview of IIoT, including its history, benefits, and top applications. If you’re looking to implement IIoT in your business or are simply interested in learning more about this topic, India’s IoT application development company in India can help. They have extensive experience developing IoT applications and would be happy to discuss your specific needs.