Liquid Flow Measurement and its Working Principle?

There are several types of flow switches. Each of them has a unique working principle that guides its design. A flow measurement tool will gauge the flow of fluids within a flow channel. There are flow gauging tools suitable for open channels. Let’s look at the standard flow switches and their principle of operation.

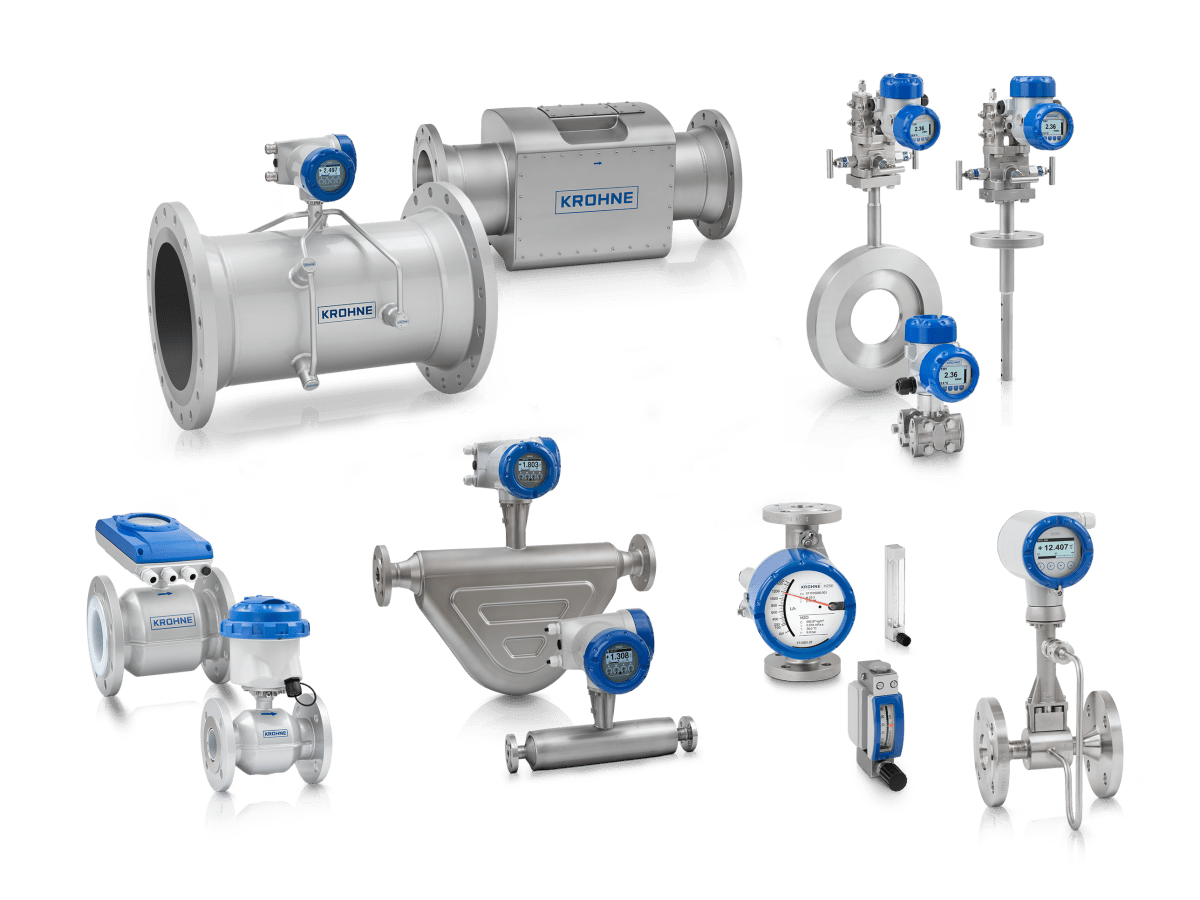

Turbine Flow Meters

This is the most common water flow meter you can find- You can add an alarm or response system to make it a flow switch. The meter has some rotating vanes within the gauging area. It works when a fluid passes through it, pushing the vanes forcing rotation. You get the flow rate by the number of cycles per unit time.

Turbine flow meters can be paddle wheel, stunt, or propeller designs. All the inner parts rotate when the fluid moves within the flow channel; These flow switches are helpful in both closed and open channel flows.

Turbine flow switches give you the volumetric flow rates of fluids. The flow rate directly relates to the speed of rotation of the blades.

The main pitfall of the turbine flow meters is that they trap suspended solids. Thus, with time it can clog. Turbine flow meters are costly to maintain. Unless you use them with pure fluids, you should clear the solid particles before clogging the system.

Vortex Flow Meters

Vortex flow meters do not have a moving part within the system. They are among the non-mechanical meters that you can use with any fluid.

Vortex flow measurement tools use the principle of vortex shedding. Hence the meter should have a disruption from within the channel flow. The disruption causes the creation of Eddie’s downstream. The frequency of eddies shows the speed of flow of the fluid. The higher the flow rate, the higher the frequency of the eddies.

Viscosity can affect the creation of eddies. Unless the fluid is under high heat and pressure and has a high flow rate, it’s hard to create eddies in the viscous fluids. Thus, vortex flow switches are best for water-like liquids.

Electromagnetic Flow Meters

These meters use the principle of Faraday’s law of induction. The meter has a magnet. Thus, the fluid flows through a magnetic fluid. Since many fluids have electric traits, they create a voltage as they pass the magnetic fluids: the voltage raises or lowers with the increase in the fluid flow rate.

EM flow switches have a challenge of low accuracy. Thus, you can’t use them in custody transfer. However, they are cheap and reliable in firms that need a guess flow rate.

These meters are useful where it’s hard to use vortex or turbine flow switches. They are resistant to cloning since they have no moving parts. Also, you can get the meter in a variety of materials. You can choose one that can suit your fluid traits.

Ultrasonic Flow Meters

Ultrasound is not only valuable for hospitals. It was added to fluid mechanics to create ultrasonic flow meters. These meters use sound signals to track the speed of fluids downstream.

An ultrasonic flow switch will send a signal downstream and another upstream. Since the fluid is in motion, it will accelerate the speed of the signal upstream. However, the upstream signal will meet resistance. Hence, the meter will compare the travel time of the two signals to determine the flow velocity.

The calculations will give you a volumetric flow rate. The calculations should never worry you. The meter has an automatic system that calculates the flow rate and sends the readings on the screen display.

You can have the screen display on the field of operation. Alternatively, you can have a web interface where you will receive the meter readings remotely.

An ultrasonic flow meter is non-intrusive. That makes it durable and valuable in a wide range of fluids. However, it doesn’t work well with pure fluids. It needs a liquid with particles that can carry the sound signals.

Coriolis Flow Meters

Coriolis flow meters are used as another name for Mass flow meters. However, it’s not the only type of flow meter under the mass flow meter category. Coriolis flow meters use the Coriolis principle. The concept sounds complex but bears accurate results.

Mass flow meters give the meter readings as mass flow per unit time. Thus, you can use the meter in custody transfer, where you gauge the flow by the mass movement of the fluid.

Pressure and heat levels do not affect the functions of Coriolis flow meters. However, you should select a material wisely so that it can handle extreme temperatures and pressures.

Positive Displacement Flow Meters

Positive displacement flow meters work by holding and releasing a known volume of water. Thus, it has oscillating parts that alternate each time one part gets filled. They have a slight resemblance with turbine flow meters. The turbine flow meters do not hold the fluid but rotate as the fluid flows past the meter.

Positive displacement has a high degree of accuracy. Also, they are insensitive to viscosity, temperature, and pressure. The meters exist in various materials to cater to different fluid traits in every flowing fluid.

There are several types of flow meters under this class. They all work under the same principle. However, the names of the switches come from the design and shape of the rotating part of the meter.

Open Channel Flow Meters

These flow meters work in open channels. You can also use them in non-pressurized sewer systems, tunnels, and partially filled pipes, ricers, canals, and streams. In most cases, the meters use the cross-sectional area and depth to estimate the flow rate.

Weirs and flumes are among the oldest types of open channel flow meters. Also, the weirs operate by the principle of obstruction. The weir will create a high head upstream due to the barrier. Then the meter will release the fluid according to the shape of the weir. You can estimate the flow based on the level the fluid is leaving the weir.

Conclusion

Liquid flow measurements vary based on the uses and needs of a firm. You can call them flow meters or water flow switches. Although you can use the names interchangeably, flow switches should have an alarm system. They should alert the operator of any action that needs to be taken. Also, they can activate the shut-off/ switch-on valve.