Safety-First With Cast Resin Transformers

What is transformer?

A transformer is known to be the best devices seen in electrical system that connects the circuits that are function at various voltages .They are normally used in applications where there is a requirement of AC voltage adaptation from one voltage level to a different one. In a wide-ranging term transformers are considered as 2 kinds they are power transformers and electronic transformers. It is possible either to reduce or upsurge the currents and voltage with the help of the transformer in AC circuits depending on the needs of the device or load and electrical equipment. Numerous applications use extensive diversity of transformers comprising instrumentation, power and pulse transformers.

Types of Transformer

There are numerous kinds of transformer applied in the electrical power method for dissimilar drives, such as distribution, generation, utilization and transmission of electrical power. The dissimilar kinds of transformer are Step down and Step up Transformer, Power Transformer, Instrument transformer, Distribution Transformer comprising current and Potential Transformer, Three phase transformer, Single phase and Auto transformer, and so on.

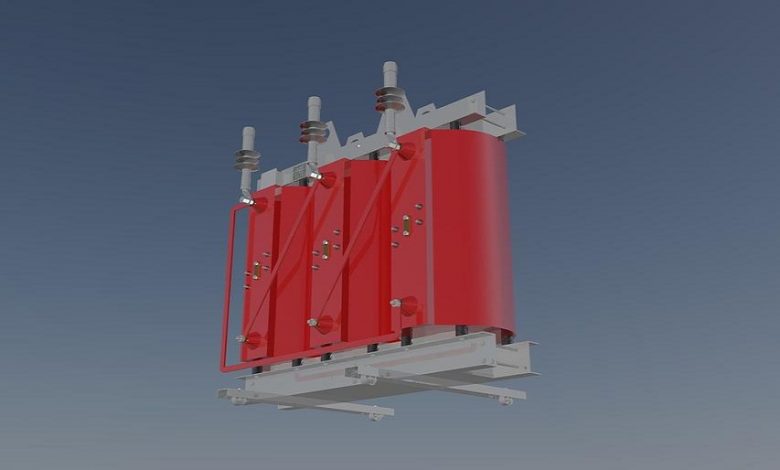

Cast-resin transformers

Cast-resin power transformers covers the windings in epoxy resin. Such kind of transformers abridge connection because they are not wet, without freshening oil, and so needed no fire-proof arch for inside connections. The epoxy defends the windings from corrosive and dust atmospheres. Talking about efficient design, dry type transformer rank higher than the older types of transformers. The latter ones had a haunting past of cracking due to heating and cooling in the curves of the windings, especially in the cast-resin transformers but the dry type transformer is crack-resistant with its glass fiber reinforcement in the connection windings.

The most understandable security feature of cast-resin transformers is the use of epoxy resin as compare to the oil. For instance, dry-type transformers include alumina trihydrate in the resin formula that lessens the fire risks in 3 methods. If a unit is unprotected to flumes, the material:

- Makes a bending protection of alumina

- Grows a barrier of water gas

- Holds superficial temperature under the point of explosion

- As a result of such qualities, dry-type transformers are in real a self-extinguishing. With a net calorific worth of 10 mega or kilogram rather than to 30 MJ/kg for the oil used to cloister liquid kind transformers, cast-resin units can be comfortably connected inside, without any fire protections.

They accounts for a huge proportion in coatings, which are in common:

- Outstanding chemical resistance specially alkali.

- The film bond, particularly for metal.

- An amazing electrical insulation and heat resistance

- Amazing color and paint retaining.

Not only to the resisting flames have a cast-resin transformers even gives out lesser amount of toxic smoke as compare to oil-insulated types. The meaning of this is that firefighters are cable to more securely access parts all over a transformer must a blaze happen to take place nearby. Cast resin transformers are many steps ahead of oil transformers, however these cast resin transformers are created as per the conventional technology. These use a continuously wound coil whose conductor includes of an aluminum coil and the winding or layer insulation of foil. The lining agrees only to insulation class and also such qualification is touches in the combination with the whole insulation method without any thermal reserves.

Selecting the correct transformer

When selecting the best Cast resin transformers, there are 2 important factors to check: the application and the other is a load. Numerous factors should be gauged judiciously while making a selection, to safeguard that the requirements of both primary problems are met.

To use a formula, it is characteristically an easy choice to select smaller transformers. A unit having a kVA rating that is superior from the predicted load could quickly be chosen up. But if you are choosing a big unit for an electrical utility method, to be part of a huge distribution system, you are naturally making a quite big investment therefore the assessment procedure is very much thorough and elaborate.

There are 3 main questions that influence your choice:

- Does the selected unit have sufficient volume to handle the predictable load and also do they have a specific amount of overwork?

- Will the volume of the unit be increased to keep up with potential upsurge in load?

- What is the life expectation of the unit? What are the original, connection, working, and preservation costs?