A company specializing in providing advanced process control solution services can help your business.

Do you need an advanced process control company?

Whether you run a small business or operate a large-scale factory, the answer is probably ‘yes.’

Advanced Process Control (APC) refers to sophisticated techniques and technologies used to collect and analyze industrial process data. This information can be valuable in controlling the process, forecasting future performance, and detecting faults before they become a problem.

Large-scale processes such as electricity generation & distribution, pipeline transmission of oil & natural gas, public water systems, and transportations (railroad and metro) use advanced process control companies for using APC solutions. It can also be valuable for small business owners who run a manufacturing plant or an assembly line—in other words, for all types of businesses.

Advanced Process Control: A Vital Part Of Business Success

APC plays a vital role in ensuring that a business remains competitive and profitable. Many companies have been forced to close because they did not adapt quickly enough to market forces and changing economic conditions. APC can be very useful in these circumstances.

Advanced Process Control is also essential to the smooth operation of large organizations such as public utilities. It enables you to collect enormous amounts of information about your organization, and this data can be used for informed decision-making.

What Are The Benefits Of Using Advanced Process Control Solutions?

The Advanced Process Control market is about $1 billion today, and it’s expected to grow quickly. APC automates plant processes and controls all process variables, including time, temperature, pressure, chemical concentrations, level, flow rates, and physical properties within ultra-sensitive tolerances.

The APC system benefits multiple industries by increasing efficiency through reduced variability in product and production processes. This system increases throughput and reduces waste throughout the plant. It is very popular in the oil and gas, automotive, and power generation industries.

Advanced process control provides its most significant benefit when implemented early in the design phase.

The following are the top five of the top benefits of advanced process control:

1) APC Can Increase Facility Throughput and Reduce Operating Costs-

Operating a manufacturing or production facility to maximize throughput and minimize operating costs is the number one Advanced Process Control benefit. APC allows you to monitor and control your facilities to work more efficiently.

This system also improves safety because it simplifies operations by seamlessly integrating new techniques into the existing factory automation environment. It increases output by controlling all variables at the same time. The best thing is that it offers significant cost savings by being highly efficient and accurate. Thus, APC is valuable in manufacturing, where cost is the number one competitive factor.

2) APC Is Useful For Improving Plant Safety-

The Advanced Process Control market provides significant value by making plants safer for employees, customers, and neighbors. APC continuously monitors plant processes to detect changes in the facility’s operating environment immediately.

Manufacturing plants can use APC to improve safety by integrating into other APC systems that monitor hazardous chemicals or equipment conditions that impact health and safety. It can also improve safety by providing real-time information about current conditions for operators to better assess plant conditions before making operating decisions. The system teams up with Advanced Security solutions to provide comprehensive protection of any plant environment.

3) APC Increases Operational Efficiency-

Advanced process control increases plant output and profitability by providing increased throughput, reduced production time, safer facilities, and reduced operating costs. APC provides the reliable support needed to maximize APC benefits and capabilities

4) APC Provide Real-Time Information-

An Advanced Process Control company provides significant value by providing real-time information to operators, APC system developers, and engineering teams. The system provides analysts with the APC data they need to improve operating results and make better decisions about next-generation APC capabilities. Advanced process control also provides real-time information that helps identify problems and opportunities for improvement before they become costly issues.

5) APC’s Are Intuitive and Flexible-

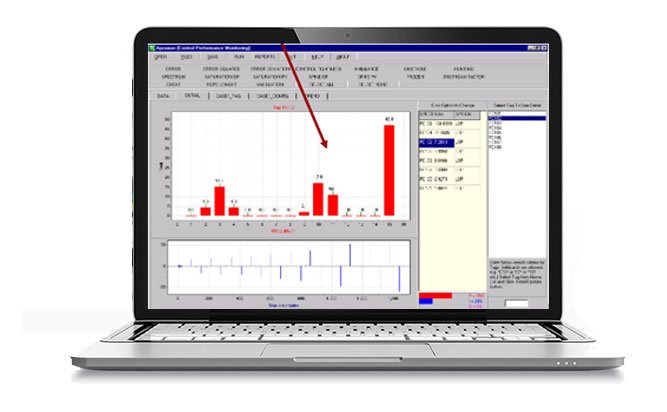

Advanced process controls are flexible and intuitive. APC enables integration across the plant floor, which increases productivity by reducing errors and outages. Because APCs are flexible, users can use them on a variety of mobile devices, such as laptops and tablets.

The Bottom Line

Enterprises are investing more in advanced process control companies for APC software solutions to increase competitiveness. Advanced process control is important for planning, management, and coordination across the APC organization. It is an investment that businesses should not overlook, especially businesses that highly rely on APC solutions.